Collection: Cold Processed Soap

Cold processed soap making is the original, traditional method of making soap.

~

Cold processed soap making combines fat or oil (animal or plant based) with sodium hydroxide (or lye) which is then blended with your choice of additives. Once these ingredients are blended together, a chemical reaction called saponification takes place (usually around 48 hours) and the previous lye is completely consumed and transformed into soap! To ensure a safe product, cold processed soap must be cured for about 4-6 weeks.

This method gives makers full control of the ingredients within the soap, and the slower curing process assures a superior product in the end.

-

Bare Naked | Goat Milk Face + Body Bar

Regular price $10.00 USDRegular priceUnit price / per -

Big Bend | Grass-Fed Tallow + Red Clay

Regular price $10.00 USDRegular priceUnit price / per -

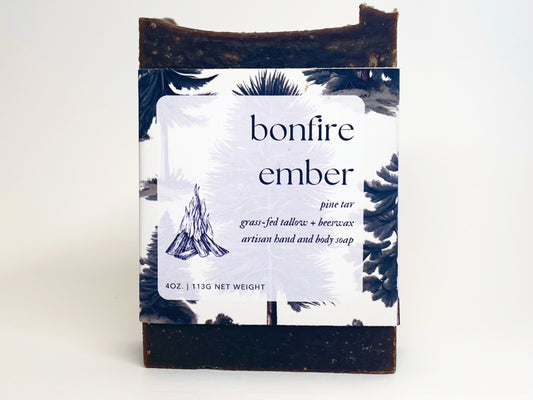

Bonfire Ember | Grass-Fed Tallow + Pine Tar Bar

Regular price $10.00 USDRegular priceUnit price / per -

Charcoal & Tea Tree | Activated Charcoal + Grass Fed Tallow Bar

Regular price $10.00 USDRegular priceUnit price / per -

Coconut & Rose | Vegan Shea Bar

Regular price $10.00 USDRegular priceUnit price / per -

Desert Bloom | Prickly Pear Cactus Bar

Regular price $10.00 USDRegular priceUnit price / per -

Happy Hippie | Vegan Shea Bar

Regular price $10.00 USDRegular priceUnit price / per -

Honey Lemon | Grass-Fed Tallow + Wildflower Honey Bar

Regular price $10.00 USDRegular priceUnit price / per -

L'Etoile du Nord | Grass-Fed Tallow Bar

Regular price $10.00 USDRegular priceUnit price / per -

Lavender Field | Grass-Fed Tallow + Goat Milk Bar

Regular price $10.00 USDRegular priceUnit price / per -

Miel y Cafe | Grass-Fed Tallow + Chicory Coffee Bar

Regular price $10.00 USDRegular priceUnit price / per -

Molly's Soap | Grass-Fed Tallow + Wildflower Honey

Regular price $10.00 USDRegular priceUnit price / per -

Sea Salt & Lime | Coconut Milk + Pacific Sea Salt Bar

Regular price $10.00 USDRegular priceUnit price / per -

Soap Misfits | Cold-Processed Sample Pack

Regular price $8.00 USDRegular priceUnit price / per -

Spiced Oatmeal | Shea + Raw Honey Bar

Regular price $10.00 USDRegular priceUnit price / per -

Texas Grapefruit | Grass-Fed Tallow Bar

Regular price $10.00 USDRegular priceUnit price / per